Precision in Roughness Measurement

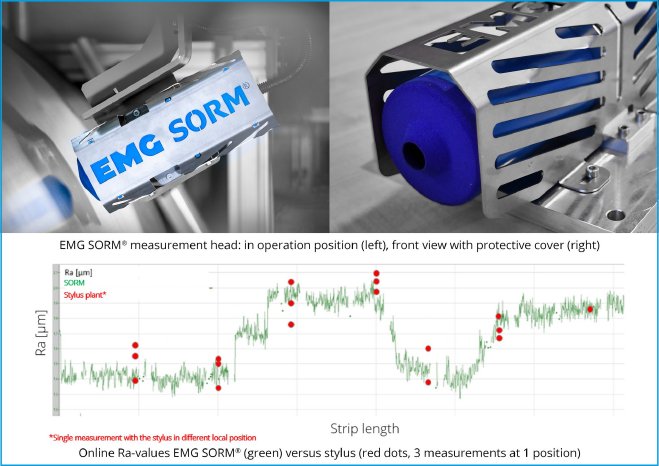

Surface roughness is a critical quality parameter in cold-rolled steel and aluminium production, particularly in automotive and high-quality grade manufacturing. The EMG SORM® system determines roughness parameters such as Ra (arithmetic mean roughness) and RPc (peak count) with a high level of accuracy.

To validate the system's accuracy, a comparison was conducted between EMG SORM® online measurements and traditional stylus-based methods. In tests conducted on a continuous galvanizing line (CGL), results from 858 coils were analysed. The findings demonstrated:

- 92 % of roughness values are within a 15 % deviation range from the reference measurements.

- 80 % of values fell within a 10 % deviation range.

Accurate Waviness Measurement for Enhanced Product Quality

Waviness, often overlooked in conventional quality control, can lead to serious issues in coating adhesion, paint finish uniformity, and structural integrity. The EMG SORM® system addresses this challenge by providing continuous, high-resolution waviness measurements (Wsa parameter).

A comparative study between EMG SORM® and a stylus instrument (Hommel T8000) was conducted on 80 samples from a continuous annealing line. The results showed:

- A strong correlation coefficient of 0.98, demonstrating remarkable consistency between the two methods.

- 80 % of values within a 20 % deviation range from the reference data.

Key Technical Data of EMG SORM®

To fully understand the capabilities of the EMG SORM® system, you’ll find its main technical specifications below:

- Strip speed limit: 350 m/min (RPc 230 m/min)

- Roughness / waviness values: Ra / RPc / Wsa

- Application fields: CGL / EGL / PL / Blanking lines / Stainless steel / Aluminium (other materials on request)

- Necessary space in plant: less than 400 mm, in production direction

- Measuring distance: 25 mm

- Measuring range (Sheet thickness): 3 mm (without focus unit)

The introduction of EMG SORM® has set a new standard in online surface quality measurement. The integration of roughness and waviness measurement in a single sensor significantly simplifies the monitoring process while improving accuracy and response time. The system has proven:

- High precision in measuring roughness values in-line with strong correlation to traditional measurement methods.

- The ability to measure different surface textures without requiring any changes to system parameters, making it highly adaptable for various production needs.

- The integration of roughness and waviness measurement in a single sensor, eliminating the need for multiple systems and reducing complexity.

- The ability to detect texture or waviness fluctuations caused by production variables, enabling proactive quality control.

- Reliable and highly accurate waviness measurement, addressing challenges in coating adhesion and visual quality.

- Seamless integration into fast production lines like CGL, EGL, blanking lines with minimal installation effort.

- There are no special safety requirements when operating the system - for example in comparison to the use of laser measurement methods.

For support or further details on how the EMG SORM® system can enhance your production processes, contact EMG Automation GmbH, visit our website at www.emg.elexis.group/en/, or reach out to our product manager, Franziska Kneisel (franziska.kneisel@emg-automation.com).

For a visual impression of EMG SORM® don’t miss the short product film @YouTube.