To ensure that filling the capsules is just as uncomplicated as inserting the capsules and coffee pods into the respective machine, Minges Kaffeerösterei now also relies on the piFLOW®f vacuum conveyor from Piab for filling the capsules. Minges has already had good experience with this type of conveyor when filling coffee powder for coffee pods.

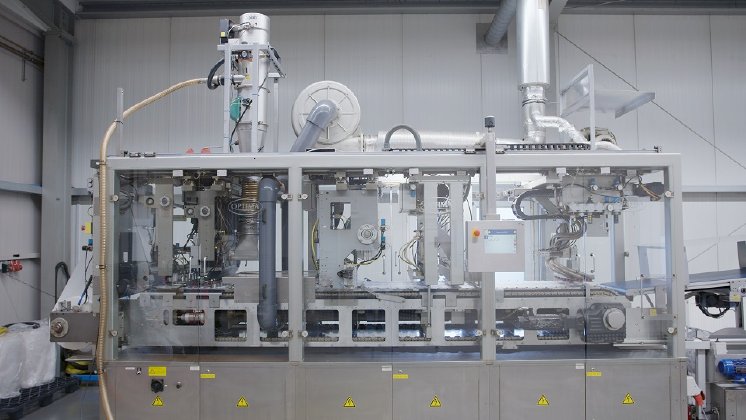

When the coffee powder is filled into the capsules, it falls from a big bag into a collecting container. From here, it is sucked into the vacuum conveyor with an over-hose. This discharges the powder into a receiver, which is equipped with a sensor. As soon as the sensor indicates that the filling quantity has been fallen short of, the piFLOW®f conveys further coffee powder into the receiver. From here, the coffee powder is fed directly into the capsule filling machine in the packaging line and the individual capsules are filled. The finished capsules are carried through a rail system of the final packaging machine, which sets up the corresponding boxes with the help of Piab's suction cups.

Andreas Fritz, head of technology and maintenance at the Minges coffee roasting company, explains, "We wanted a conveyor for the capsule systems that simply does what it's supposed to so that we don't have to worry about the equipment any further. It should simply run. That's why we were particularly convinced by the simplicity of the design and the robustness of Piab's piFLOW®f. Because we were looking for a simple, effective conveyor system."

"We used to employ very simple conveyors with gravity dampers, but the filters were constantly clogged," he continues. "Because Piab's vacuum conveyor has hardly any moving parts, it requires little maintenance. The filters clean themselves after each cycle with a filter shock. So we have been able to solve the problems we had with the old technology quite easily with the piFLOW®f. The vacuum conveyor has also reduced dust in the room due to its closed system. This allows us to achieve better occupational safety while avoiding contamination of the coffee by particles from outside."

"When changing products, the piFLOW®f is easy and straightforward to clean. In just a few simple steps, the entire conveyor, including filters and seals, can be disassembled, cleaned, and reassembled for the next production run without the need for tools, thanks to the quick-lock system," adds Francisco Diaz Arriola, Piab's responsible area sales manager.

"When it comes to filling the coffee pods, the switch to the Piab vacuum conveyor has also helped us to improve the quality of the product. This is because originally, the freshly roasted coffee was brought into the machine. Although this sounds good at first, it led to aroma losses. That's why we opted for the Piab vacuum conveyor, through which we now feed a cooled coffee, previously ground via a separate grinder, onto the system and package it into the 7-gram coffee pods, which are picked up from the belt with Piab's suction cups and placed in the packaging unit," says Andreas Fritz, explaining the decision to use the very first Piab vacuum conveyor at Minges.

The piFLOW®f vacuum conveyor is operated with Piab's patented COAX® multistage ejectors in the vacuum pump. The vacuum is generated by ejecting compressed air from a nozzle system. This enables both high efficiency of the system and a high absolute vacuum level. Blockages in the conveying line are thus virtually eliminated.

"In addition to the technology, the good cooperation with short response times and firm statements was also important for us, as well as spare parts reliability and service calls that are arranged according to our schedule, as well as a contact person who is always available. Because fast support when needed helps us to reduce downtimes," Andreas Fritz concludes his explanation of the reasons for working with Piab.

The piFLOW®f is widely used in industries where food quality is required. It is often used as an alternative to mechanical conveyors when dust-free conveying or low maintenance is necessary. Another advantage is that the COAX® technology used is the most energy-efficient way to generate vacuum. Piab's conveyors for the food industry are equipped with a stainless steel (ASTM 304) housing and the seals, which are in direct contact with the product being conveyed, meet FDA and EU 1935/2004 standards to comply with the requirements of the food industry. Piab's conveyors are certified according to ATEX dust. The piFLOW®p and piFLOW®t vacuum conveyors are also ATEX Gas certified. All conveyors are available with either an ejector-driven vacuum pump or a mechanical pump. The standard piFLOW®f has a capacity of 4 tons per hour, the large one manages up to 7.5 tons in the same time.