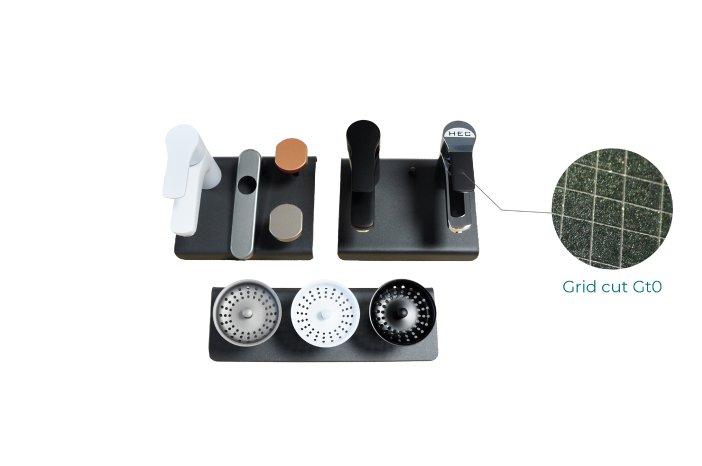

Wherever there is a demand for chrome-plated fittings with a stylish surface design in a colored, metallic, smooth or glossy look, coating plays an important role. Depending on the material to be coated, the process can be very complex and resource-intensive. Fittings, for example in bathrooms and kitchens, which are subject to heavy use, must be robust and corrosion-resistant. "Metallization alone is not enough to achieve long-lasting adhesion of the coating to the material surface," says Andreas Michalske, sales engineer at Venjakob.

Venjakob presented the patented coating process at this year's Paint Expo in Karlsruhe/Germany, the world's leading trade fair for coating technology.

Up to 70 percent savings - without any loss of quality

For the fittings industry, the high-end coating process (HEC) could be the solution to many challenges. This involves a special pre-treatment in a high-vacuum system. The surfaces of metal and plastic parts are given an antistatic functional layer with increased surface tension. This simplifies the subsequent coating process. Pre-cleaning the surface with ionized air is completely sufficient. "In the subsequent coating process, we can manage with layer thicknesses of between 12 and 25 µm. Paint consumption is reduced by up to 70 percent.

The components treated in this way have a high-quality appearance and pass all the necessary tests," explains Michalske. It is important to know that the fittings industry places higher demands on components than the automotive industry, for example. There is a so-called boiling test, in which the components are placed in a boiling medium to test how long they remain intact or do not release any harmful substances. Components in the automotive industry only need to "boil" for one hour. In the German fittings industry, 100 hours are required.

Less effort for better results

The high-end coating process is completed in just a few steps. The components are pre-treated in a special HEC high-vacuum process and a specially generated vacuum plasma. They are then removed and fed to the coating system for coating. The high-vacuum pre-treatment replaces passivation and phosphating, thus reducing the number of pre-treatment steps. There is no edge alignment or edge build-up during the subsequent coating process. The high-end coating process offers many other advantages and can also be integrated into existing series processes.

Fact box HEC-process (extract of advantages)

- industrially inspected, tested and proven

- compliance with standards of the fittings, hardware and automotive industries

- one-coat system, without adhesion promoter or additional primer

- can be integrated into existing series processes

- no clean room conditions necessary

- paint material savings of up to 70%

- no disposal costs

- replaces passivation and phosphating

- no additional chemicals or water required

- environmentally friendly, free from chrome and heavy metals