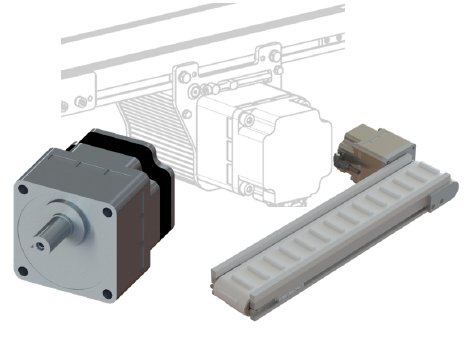

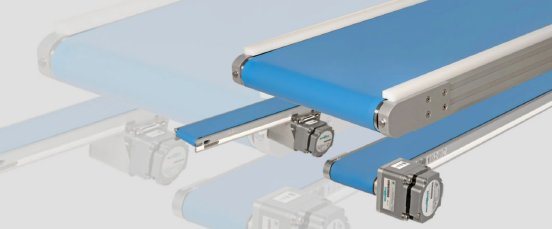

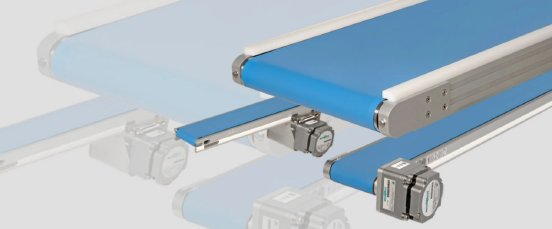

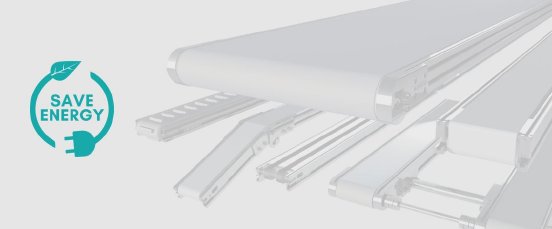

Montech offers customized solution: inclined belt conveyor with belt bend

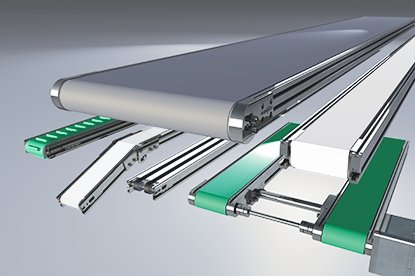

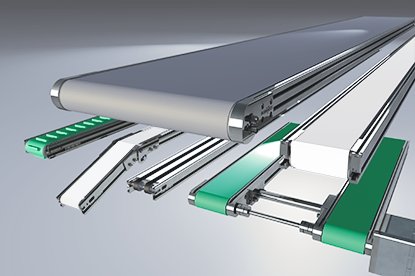

Montech now offers an inclined belt conveyor with belt bend that enables flexible and space-saving material transport over different height levels. Ideal for demanding production environments, it improves production flow and logistics thanks to its precise and robust design.