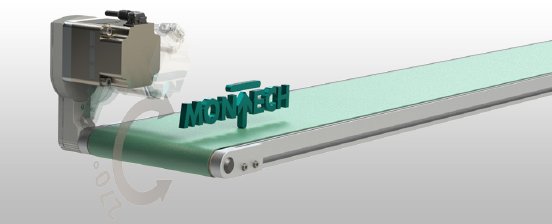

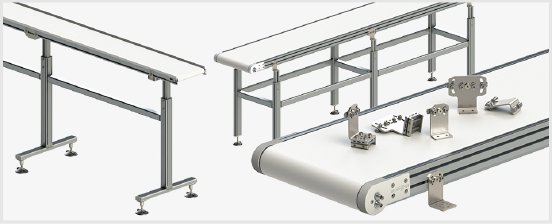

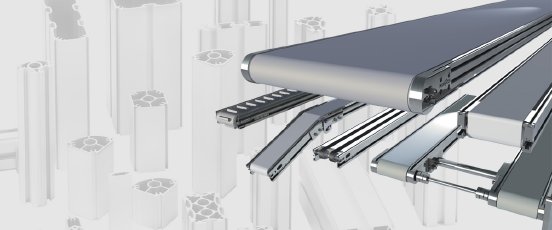

Semi-standardized TB30 transport conveyors with brushless motors

In our semi-standardized TB30 belt conveyors, the Italian company Sintech has found the perfect solution for its loading and unloading cells and inspection lines for the medical and pharmaceutical industries. They are equipped with brushless drives, medically specific side guides, and low-friction belts. This is how the TB30 belt conveyors fulfill all the requirements of the medical and pharmaceutical sectors with regard to speed, quality, and precision.