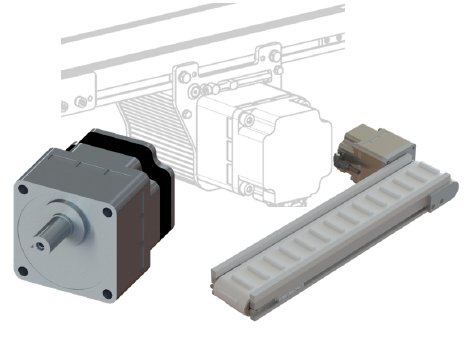

Increased efficiency thanks to Montech's belt conveyors

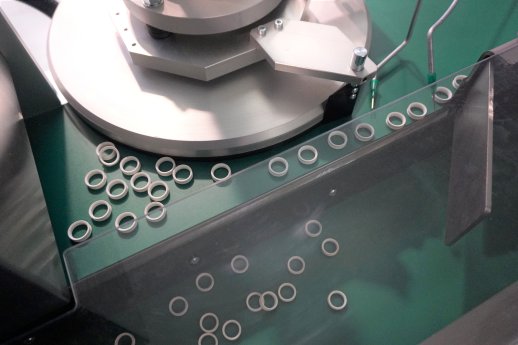

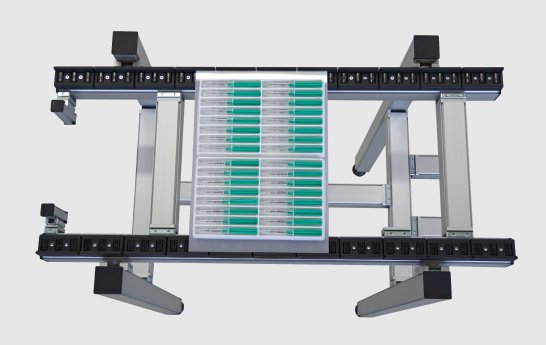

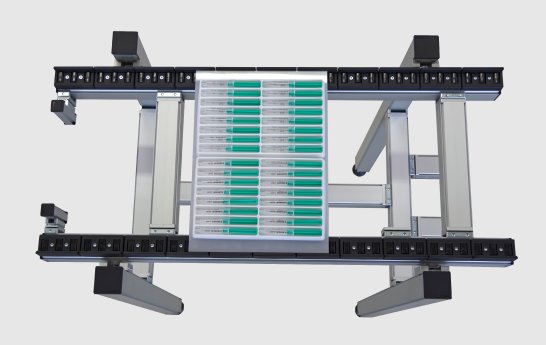

Doss Visual Solution optimizes its production lines with Montech's TB30 and TB40 belt conveyors. The compact hybrid version of the TB30 is ideal for integration into complex machine designs, while the TB40 is suitable for unloading large parts. These standardized and customizable conveyors offer time, cost and energy savings as well as a complete solution from a single source, including comprehensive support and certifications.